"If you always do what you've always done, you'll always get what you've always got."

Our technical services are more than just "analysis" – they are practical tools for real change. From the operations management to the line supervisor, we understand how technical excellence is achieved: through clarity, metrics, and continuous improvement.

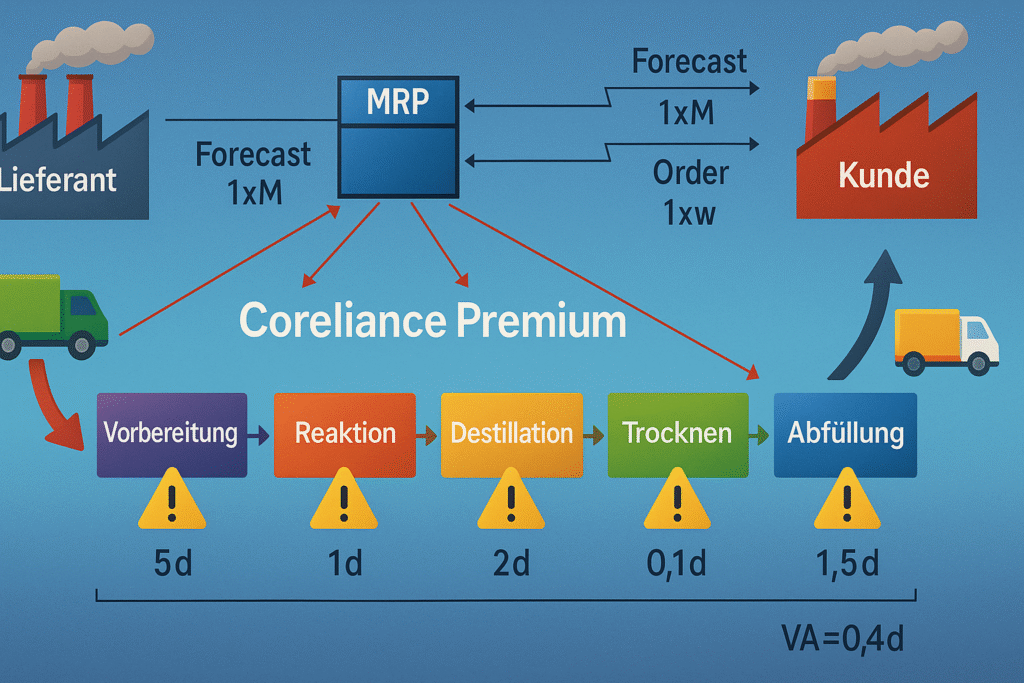

Value Stream Mapping (VSM)

"You can only improve what you understand."

VSM creates precisely this understanding – visually, holistically, and across teams.

- Kick-off with process owners

- Gemba Walks for real process observation

- VSM-Workshops with interdisciplinary teams

- Visualization & Analysis of material and information flows

- Derive measures and prioritize them (e.g., with Pareto or Impact-Effort Matrix)

Debottlenecking & Bottleneck Analysis

Bottlenecks determine the pace of any process.

Our bottleneck analysis systematically reveals where the flow is obstructed and how to restore it.

- Process Metrics Analysis (e.g., OEE, throughput, cycle times)

- Identification of Bottlenecks along the value chain

- Gemba Walks & Observation of Actual Operations

- Simulation & Scenario Evaluation to shift bottlenecks

- Developing Measures to expand capacity or relieve processes

- Prioritization with Bottleneck Matrix or Theory of Constraints (TOC)

Asset Effectiveness Tracking

Assets are the heart of any production. Asset Effectiveness Tracking shows how well this heart beats – and where it falters.

- Capturing and visualizing OEE (Overall Equipment Effectiveness)

– Availability, performance, quality at a glance - Data-driven analysis of machine and equipment metrics

– e.g., downtime, microstops, utilization - Integration of MES, SCADA, or IoT data sources

- Identification of loss sources

– e.g., unplanned downtime, slow cycles, waste - Development of measures to increase efficiency

– e.g., TPM approaches, maintenance strategies, training - Dashboards & KPI tracking for continuous improvement

TPO: Technical Process Optimization

"You can only produce steadily if you know what the ideal run looks like."

Our TPO: data-based, predictive, and adaptive.

With methods like Golden Batch and PAC, we extract the best from every process run – reproducible and efficient.

- Golden Batch Analysis

– Identification of the optimal process flow based on historical top batches - Deviation Analysis in Real-Time

– automatic detection of target-actual deviations during production - PAC (Predictive Advanced Control)

– model-based control for dynamic process management - Integration of process data, MES, and lab values

– for complete transparency and traceability - Root Cause Analysis & Action Plan Development

– e.g., using 6M or Fishbone diagrams - Continuous Improvement through Closed-Loop Learning

We’ve got your back – so your production runs smoothly!

While you and your team focus on daily operations, we analyze your process data in the background – precisely, structured, and targeted.

Our Promise:

- We relieve your Team by identifying data-based optimization potentials.

- We provide concrete action recommendations to increase your maximum sustainable production performance.

- We work closely with your team but without obstructing it – efficient, pragmatic, and solution-oriented.

Your Advantage

More output, less downtime – with a partner who thinks in the background so you can deliver upfront.